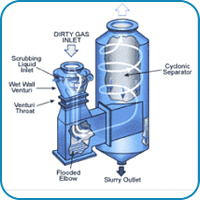

Ventures Scrubbers: A venture is a tube with a narrow throat that increases the velocity and lowers the pressure of the liquid passing through it. In venture scrubbers the inlet for the dust filled air stream is shaped like a venture. When dusty air enters it, the speed of the air stream is increased to 15000-20000 feet / minute. By adding 4-6 gallons of water pr 1000 CFM of cleaned air at the venture throat, dust is trapped in slurry to form very fine droplets. The high air velocity helps fine dust particles to be collected efficiently. After dust is captured by the water and formed into slurry, mist is eliminated from clean air stream by mist eliminator. Slurry is directed to the scrubber outlet.

It is necessary to keep the air stream close to saturation point or in a 'humidified' state to prevent dust from escaping as slurry evaporates. This could be a problem since liberated air normally does not return to the work environment. Another phenomenon that could occur is that of plumes that form due to mixing of hot air and cold air when condensed water vapor descends ground ward due to heavy water droplets, sometimes miles away.

| Uses of Wet Scrubbers: |

Wet Scrubbers are most often used - To separate explosive solids from air streams - Where slurry could be reused (either in other parts of process or sold) - Where chemical reactions could be generated with scrubbing action - To absorb air |

Wet scrubbers have low capital costs and require small spaces to install. They can be used to treat high temperature and high humidity air streams and have the capability to capture both air and sticky particulates. However they have high operating costs, require a pre-cleaner for heavier dust loadings, cause water pollution and are likely to erode at high velocities.